Electromagnetic interference (EMI) is prevented by ferrite beads in two directions: from a device and to a device. A conductive cable can operate as an antenna, allowing radio-frequency energy to be sent through the wire, which works as an accidental radiator. The bead is essential in this scenario for regulatory compliance and to minimize EMI.

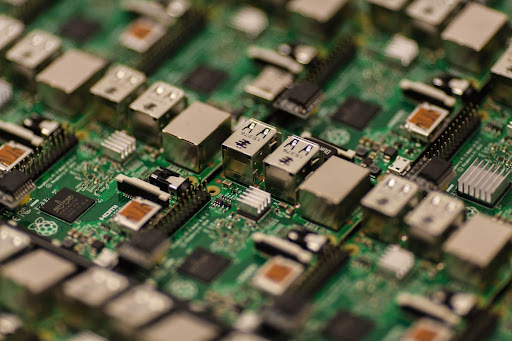

If additional EMI sources, such as domestic appliances, are present, the bead stops the cable from functioning as an antenna and collecting interference from all the other devices. On exterior cabling, big ferrite beads are prevalent. Internally in circuits, ferrite chip beads of various sizes are utilized on wires or around the pins of tiny circuit-board components including transistors, connectors, and integrated circuits.

The power supply problem has been plagued by a multitude of erroneous rules-of-thumb, “black magic” design standards, and misunderstandings about what works and what doesn’t over the years. The employment of ferrite beads as just a technique of regulating and confining EMI is one of the most contentious topics. When it comes to the usage of ferrite beads, there is a lot of contradicting information, making it difficult to know what is true and what is not.

The underlying problem is that because of the vast volume of data connected with the incorrect information, it appears to be correct. To add to the confusion, some IC application notes will propose the use of ferrite beads as a method of decreasing noise.

Table of Contents

Ferrite Beads: Their History

To clear up the initial misunderstanding, ferrite chip beads (https://en.wikipedia.org/wiki/Ferrite_bead) are not beads. They’re mini-inductors. It’s a toroid, not a bead, that keeps referring to as a bead. (A toroid is just a coil of shielded or enameled wire coiled on a powdered iron doughnut form.)

It’s utilized in electrical circuits as an inductor, particularly at low frequencies when huge inductances are required. They’ve been utilized as transformer cores for millennia). Ferrite inductors will be alluded to as ferrite beads in order to preserve uniformity with the rest of the industry. Ferrite beads, like other surface-mount components like resistors and capacitors, are surface-mount components. They’re also accessible in the same sizes as the originals.

The Use of Ferrite Beads in History

The usage of ferrite beads in PCB layouts dates back to the late 1980s when bespoke CMOS chips were finally fast enough to produce frequencies in the EMI range. When EMI experts inserted ferrite beads into the device’s power lines, the EMI vanished since the component couldn’t longer switch quickly enough to generate the EMI band’s frequencies.Visit here

As a result, the ferrite bead served as a band-aid. It worked, and it stopped the noise, but it also stopped the component from operating at full velocity (i.e. switching fast). When ferrite beads were originally used, speed was not a priority in terms of rapid edges.

For most items, the frequencies included in radiated EMI vary from 30MHz to 1GHZ. The ferrite bead’s resistance prohibited the IC from drawing power from the power source at high frequencies. As a consequence, the IC package had no high frequencies that may pose an EMI concern. Eliminating the source or the antenna is among the two strategies to manage EMI. This method existed for as long as the IC or ASIC was not required to function with quick edges or fast processing.

Prior to the introduction of 130 nanometer integrated circuits, most circuits were sluggish enough that a very low resistance source at a higher frequency was unnecessary. PDSs worked in spite of nasty habits rather than good engineering methods in this situation.

What Are Ferrite Beads Used For?

When a ferrite bead is connected in series with an IC’s power line, the PDS’ performance degrades, as evidenced by the device’s increased output impedance. It’s vital to note that a power source is designed to be a voltage source, which means that the output voltage stays unchanged regardless of how much current is pulled from it. To put it another way, power sources must have zero or extreme impedance at any and all frequencies to function effectively. As previously stated, the velocity of ICs ultimately rose to the point where a ferrite bead would prohibit them from functioning properly.

Why are application notes mentioning ferrite beads?

It’s worth noting that the inductor and capacitor in a high-speed ASIC constitute a low-pass filter that keeps high-frequency noise from the power subsystem from reaching the component. Most application notes state that ferrite beads should be connected is connected to the power connections of PLL (phase-locked loop) gadgets and other “analog” circuits, such as PLLs.Visit here

Serializer/Deserializer, as noted here in this write-up on Serializer/Deserializer (SERDES).

For a variety of reasons, IC suppliers have traditionally advised the usage use of ferrite beads in their implementation notes. The second justification a vendor will provide for requiring the use of a ferrite bead is to prevent noise from entering the sensitive circuit from the power subsystem. In terms of preventing noise from entering the power network, this became more of a symptom than a solution. The issue was that the power subsystem was not built properly, resulting in noise.

The power delivery requirements of an IC are critical for an IC supplier to comprehend. This comprises the maximum delta I that perhaps the circuit may require of the power delivery system, as well as the greatest delta I that now the circuit may require of the power delivery system.

This comprises the maximum delta I that perhaps the circuitry can require of the power delivery system, as well as the maximum permissible delta-V at what frequency (ripple). It is difficult to create a workable, trustworthy PDS without this knowledge. One of the specifications in reading the requirements for a part, along with an operational amplifier, is the power distribution rejection ratio. This is a measurement of how much fluctuations in the amplitude of the power supply impact the device’s output. For digital ICs and PLLs, such measurements are achievable.

The notion that integrated circuits are mere “logic” and don’t require this degree of characterization is a holdover from the heyday of TTL when tolerance was so high. The notion that ICs are just “logic” and don’t require this degree of definition dates back to the days of TTL when VCC fluctuations were tolerated so well that it wasn’t required to account for such.